Ukuvalwa komngceleokunamathelayo okuncibilika okushisayos asetshenziswa kakhulu emisebenzini yokuvala onqenqemeni eshidini, futhi ukujiya komugqa onqenqemeni bubonisa ngezinga elithile izinga lokushisa umugqa onqenqemeni ongamelana nalo ngeyunithi ngayinye yesikhathi. Izinamathiselo ezincibilikayo ezincibilikayo zokuqinisa amazinga okushisa aphezulu kanye nezimfuno ku-substrate, futhi kwesinye isikhathi ukuwohloka kwebhendi enqenqemeni ngesikhathi sokuvala onqenqemeni nakho kuvamile.

Ukuguqulwa kwamapheshana onqenqemeni akubangelwa izinkinga zekhwalithi nge-adhesive encibilikayo eshisayo kanye ne-substrate esetshenziselwa ukuvala onqenqemeni. Ucwaningo luthole ukuthi ngenxa yokuthi izinamatheliso ezincibilikayo zokuvala onqenqemeni zihlukaniswe izinga lokushisa eliphezulu, izinga lokushisa eliphakathi nendawo neliphansi ngokwezidingo ezihlukene zohlelo lokusebenza, ngisho nokuvala onqenqemeni nokufaka uphawu onqenqemeni kwezicelo ezinobukhulu obuhlukahlukene, kuyafana nokuvala onqenqemeni kwezinamathelisi ezincibilikayo ezishisayo. Ngenxa yokuthi imininingwane yenqubo yokusebenza ayizange ithathwe ngokungathi sína, noma kukhona ukuntuleka kokuhlangenwe nakho okuthile ekusebenzeni nasekusetshenzisweni komshini wokuhlanganisa onqenqemeni, inkinga yokuguqulwa kwe-edge band ekusebenzeni kwe-edge banding ibangelwa.

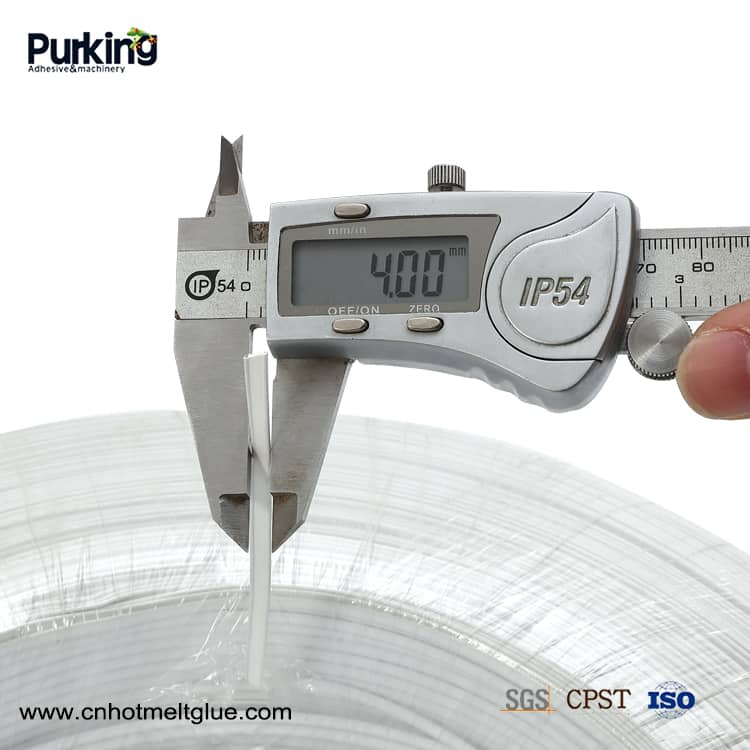

Uma i-edgebanding enogqinsi olungaphansi kuka-0.6 mm, i-edgeband ngokuvamile ikhubazekile. Imiphumela ibonisa ukuthi impahla yebhendi enqenqemeni iyathambile futhi ukunwebeka kwe-colloidal kwenzeka, okwenza ubukhulu bepuleti bungakwazi ukuvaleka. Lokhu kubangelwa izinga lokushisa eliphezulu lokunamathisela onqenqemeni lokuvalwa kwe-hot melt. Ingabe ikhona indlela yokuvimbela ibha eseceleni ukuthi ingakhubazeki ngaphandle kokuphazamisa ukusetshenziswa okuvamile kweokunamathelayo okuncibilika okushisayo? ngokuqinisekile! Ukuze sazi isixazululo, sidinga ukwazi isizathu sokuguqulwa komugqa wokuvala. Ngaphansi kwesimo sokuthi i-adhesive encibilikayo eshisayo isetshenziswa ekushiseni okulungile, isivinini sokubopha onqenqemeni lomshini wokubopha onqenqemeni singasheshiswa. Ngale ndlela, isikhathi sokuhlala se-glue ephezulu yokushisa ku-band enqenqemeni singancishiswa, inani leglue elisetshenzisiwe lingancishiswa, futhi ukuchichima kweglue ngemva kokubopha onqenqemeni kungagwenywa. Ngakho-ke hlobo luni lwejubane lokuvala onqenqemeni olunengqondo? Kunconywa ukuthi isivinini sokuhambisa sidlule ku-8 m/min.

Enqubweni yokuvala uphawu, okunamathelayo okuncibilika okushisayo kufanele kukhethwe ngendlela efanele, futhi ukusetshenziswa kwemishini yokuvala onqenqemeni kufanele kujwayeleke ukuze kuxazululwe izinkinga ezikhona ohlelweni lokukhiqiza. Ngaphezu kwalokho, ukuguqulwa kwemishini yokuhlanganisa onqenqemeni akuvamile ukwenzeka emshinini wokuhlanganisa onqenqemeni olunamahlangothi amabili, okubonisa futhi ukuthi imishini yokuhlanganisa onqenqemeni yamazinga ahlukene wohlelo lokusebenza ihlangabezana nezinkinga ezihlukene ekusebenzeni kwebhande emaphethelweni.

English

English  Esperanto

Esperanto  Afrikaans

Afrikaans  Català

Català  שפה עברית

שפה עברית  Cymraeg

Cymraeg  Galego

Galego  Latviešu

Latviešu  icelandic

icelandic  ייִדיש

ייִדיש  беларускі

беларускі  Hrvatski

Hrvatski  Kreyòl ayisyen

Kreyòl ayisyen  Shqiptar

Shqiptar  Malti

Malti  lugha ya Kiswahili

lugha ya Kiswahili  አማርኛ

አማርኛ  Bosanski

Bosanski  Frysk

Frysk  ភាសាខ្មែរ

ភាសាខ្មែរ  ქართული

ქართული  ગુજરાતી

ગુજરાતી  Hausa

Hausa  Кыргыз тили

Кыргыз тили  ಕನ್ನಡ

ಕನ್ನಡ  Corsa

Corsa  Kurdî

Kurdî  മലയാളം

മലയാളം  Maori

Maori  Монгол хэл

Монгол хэл  Hmong

Hmong  IsiXhosa

IsiXhosa  Zulu

Zulu  Punjabi

Punjabi  پښتو

پښتو  Chichewa

Chichewa  Samoa

Samoa  Sesotho

Sesotho  සිංහල

සිංහල  Gàidhlig

Gàidhlig  Cebuano

Cebuano  Somali

Somali  Тоҷикӣ

Тоҷикӣ  O'zbek

O'zbek  Hawaiian

Hawaiian  سنڌي

سنڌي  Shinra

Shinra  Հայերեն

Հայերեն  Igbo

Igbo  Lëtzebuergesch

Lëtzebuergesch  Malagasy

Malagasy  Sundanese

Sundanese  Yoruba

Yoruba  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Deutsch

Deutsch  tiếng Việt

tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  ภาษาไทย

ภาษาไทย  Polski

Polski  한국어

한국어  Svenska

Svenska  magyar

magyar  Malay

Malay  বাংলা ভাষার

বাংলা ভাষার  Dansk

Dansk  Suomi

Suomi  हिन्दी

हिन्दी  Pilipino

Pilipino  Türkçe

Türkçe  Gaeilge

Gaeilge  العربية

العربية  Indonesia

Indonesia  Norsk

Norsk  تمل

تمل  český

český  ελληνικά

ελληνικά  ελληνικά

ελληνικά  український

український  Javanese

Javanese  فارسی

فارسی  தமிழ்

தமிழ்  తెలుగు

తెలుగు  नेपाली

नेपाली  Burmese

Burmese  български

български  ລາວ

ລາວ  Latine

Latine  Қазақша

Қазақша  Euskal

Euskal  Az?rbaycan

Az?rbaycan  Az?rbaycan

Az?rbaycan  Slovensky jazyk

Slovensky jazyk  Македонски

Македонски  Lietuvos

Lietuvos  Eesti Keel

Eesti Keel  Română

Română  Slovenski

Slovenski  मराठी

मराठी  Srpski језик

Srpski језик